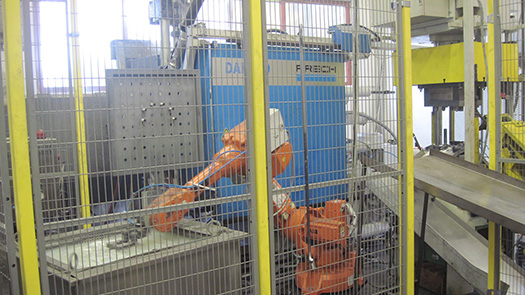

PRESSURE DIE CASTING

Casting of aluminum and zinc alloys

Casts that can be casted from aluminium weigh up to 4 kg of total weight. Depending on the size of the product order series, the number of nests and the size of the foundry tool are determined. We have a choice of cold chamber machines with a closing force of 150 - 660 tons. We use various aluminium alloys for casting, the most common being DIN AL226, AL231, AL239. The castings can then also be post-processed.

When die casting zinc alloys, castings weighing up to 0.8 kg of total lightning weight can be cast. We have warm chamber machines with a closing force of up to 50 tons. We use various zinc alloys for die casting, such as Zamak 400, Zamak 410 and Zamak 430. We also offer post-processing for these castings.

PROCESSING OF CASTINGS

Processing of aluminum and zinc castings

We use high-precision CNC machines to process die castings, which allow us to precisely process larger dimensions up to micron tolerances accurately. Casts can be processed in various ways, such as turning, milling, grinding, deburring, sandblasting and other processing methods such as painting and anodizing, which are performed by our business partners. The processed pieces are also washed. In addition to standard washing, we also offer ultrasonic washing, which meets even the highest requirements for cleanliness in the automotive industry.

INJECTION MOLDING OF PLASTICS

Plastic injection molding

We also offer injection of products from various types of high-temperature technical plastics with carbon and glass fibers such as e.g. PA 66 in PEEK. We use an automated machine with a closing force of 50 tons for injection molding, and we also use automated machines with a high-resolution camera to ensure product quality.

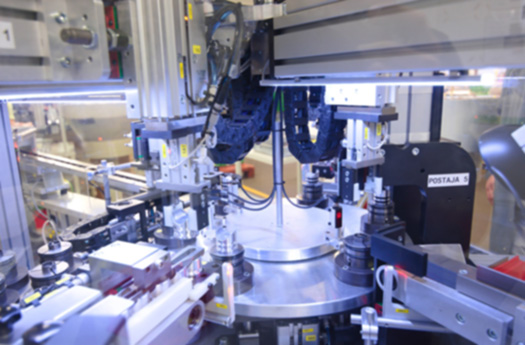

ASSEMBLY OF COMPONENTS

Assembly of components

Casts and processed pieces can be assembled into various components according to the technical specifications and requirements of the client. The company has several automated assembly machines available and is able to offer a wide variety of assembly types. The assembly process is fully automated, equipped with sensors and efficient final control.